Types of works:

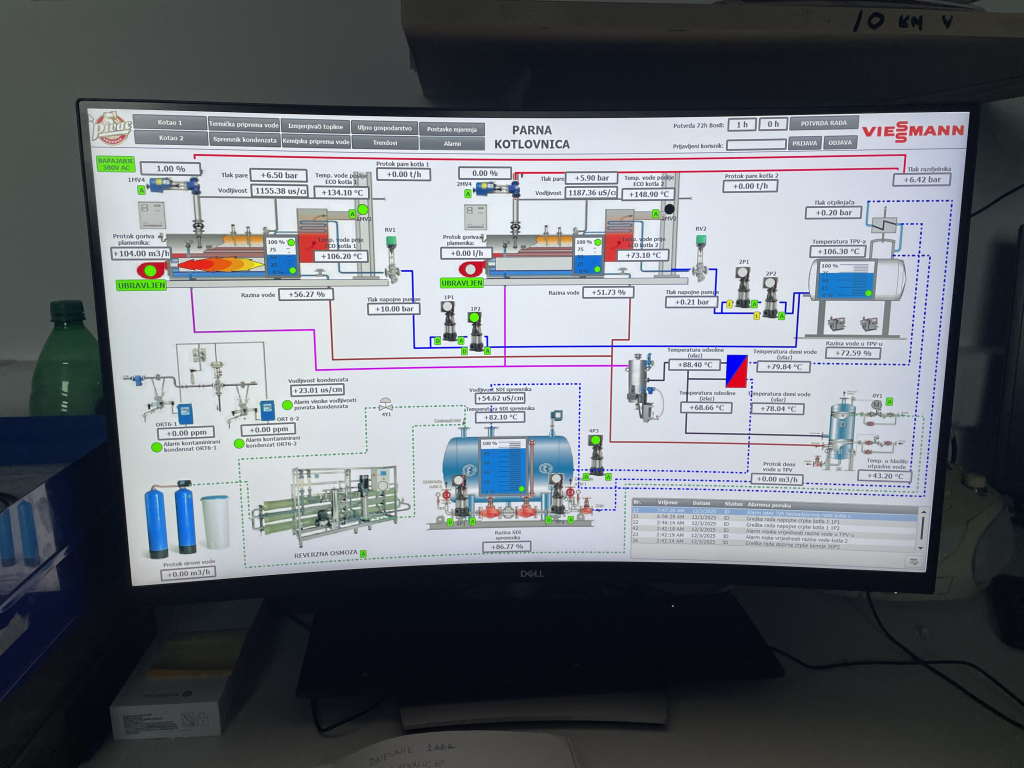

Construction of a new steam gas boiler house with a total power of 2×4 t/h of steam (two boilers with the thermal output of the combustion chamber for natural gas Q (MW) = 2.7), which includes the supply and installation of a complete distribution system, installation of chimneys, thermal water treatment and chemical water treatment.

Electrical works including execution of automation works (control of the boiler room and connection to the existing central control).

System description / Other details:

The new boiler room is located next to the existing steam boiler room (the existing steam boiler room is no longer used after the new boiler room is put into operation). The capacity of the new steam boiler room is 2 x 4,000 kg/h of steam, max. pressure 10 bar overpressure and temperature 175 ° C. Two boilers are installed in a block design and are connected in a cascade. High-efficiency oil/gas high-pressure steam boilers with an integrated heater for preheating feed water are planned, with a high degree of efficiency in the entire operating area.

The total thermal output of the boiler room is 2 x 2748 = 5496 kW.

The boilers are designed to meet the highest requirements for combustion product emissions, reduced thermal load on the combustion chamber, reduced operating costs and extended boiler and burner life. The boilers are equipped with safety and control equipment in accordance with HRN EN 12953 for 72-hour unattended operation, including automatically controlled smoke dampers at the outlet to achieve energy savings.

The boilers are equipped with burners that ensure the current ELLU and natural gas combustion standards (in natural gas operation NOx < 100 mg/m3, in oil operation < 200 mg/m3), and modulated oil and gas operation. The burners must meet the requirements of HRN EN 12953-7.

Two stainless steel chimneys insulated with special thermal insulation are installed.

A complete chemical and thermal water treatment system with a feed tank and all necessary pipelines has been installed. The boilers are equipped with feed pumps for continuous level regulation using frequency controllers. The chemical water treatment system is located in the basement of the existing building.

U prostoru kotlovnice predviđen je parni razdjelnik sa svim potrebnim priključcima i svom potrebnom

zapornom sigurnosnom pokaznom i regulacijskom armaturom. Novi razvod pare iz kotlovnice spojen je na postojeći razvod pare unutar objekta, na poziciji koja je dogovorena s investitorom. Razvod pare unutar postojećeg objekta nije predmet ovog projekta. Predviđena je prirodna ventilacija kotlovnice.