As part of its efforts to implement innovation and continuous technological advancement, Enison has installed an advanced SCADA system in its new business premises.

This move represents a significant step forward in energy efficiency management and control of production processes.

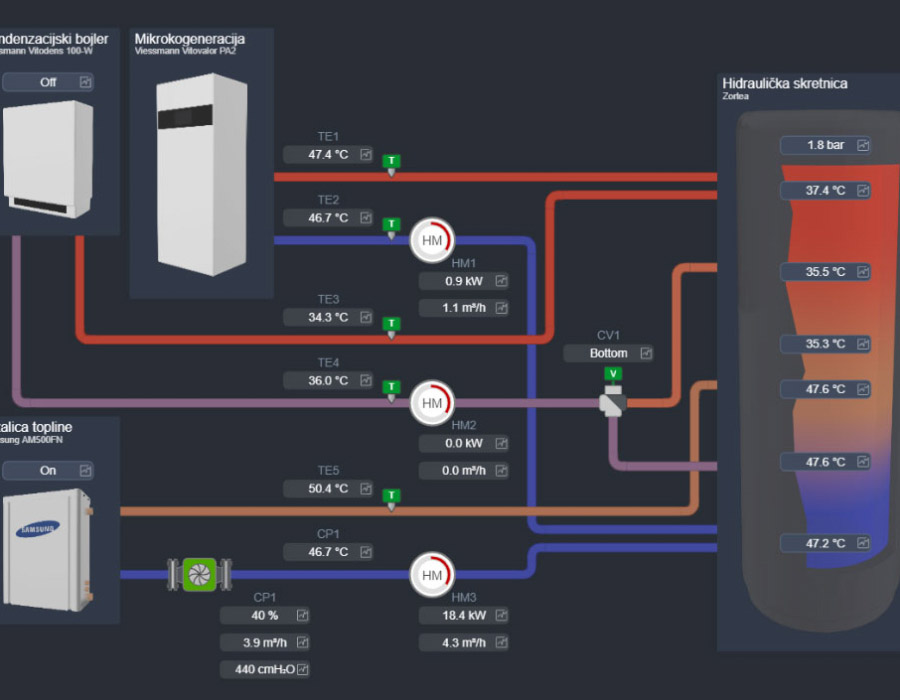

Schematic of the heating system at the Enison hall

Schematic of the heating system at the Enison hall

SCADA system

SCADA (Supervisory Control And Data Acquisition) system represents a revolutionary step in the supervision and management of industrial processes. As a computer system, SCADA enables detailed supervision, measurement and management, which significantly improves the efficiency and control of thermotechnical systems within Enison.

Designing new spaces

When designing the new office space, special attention was paid to details that support energy efficiency and innovative technological approaches. A SCADA system is integrated into the heart of the building, ensuring a high level of monitoring and management of energy resources.

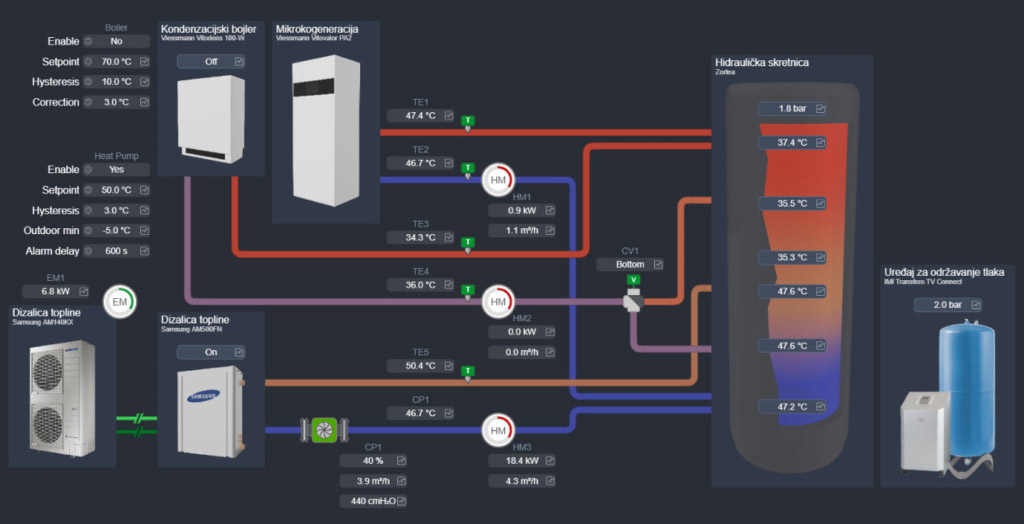

Heat sources and energy solutions

Enison’s new building uses three heat sources for maximum efficiency. The main source is micro-cogeneration, which produces heat and electricity. Secondary sources include a high-efficiency split-type heat pump and a gas-fired condensing unit, ensuring a constant and reliable heat supply.

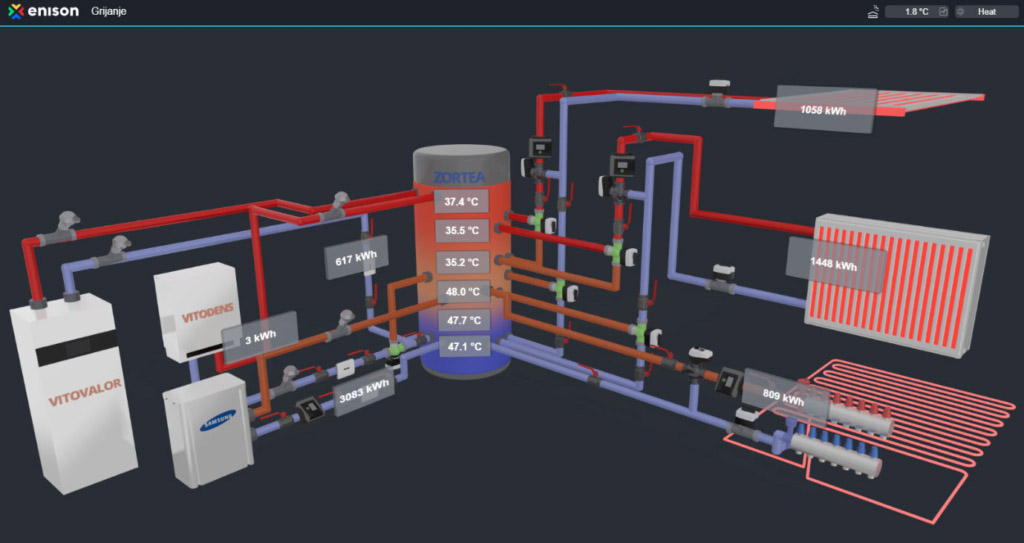

Heat production at the Enison hall

Heat production at the Enison hall

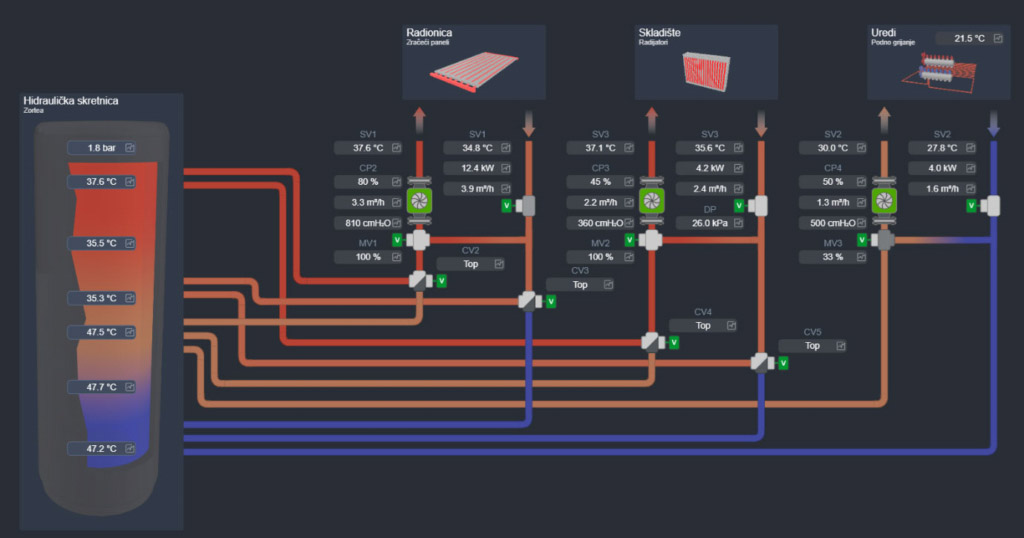

Different heating systems

According to the needs of different spaces, three heating systems were implemented: underfloor heating in the office areas, steel plate radiators in the warehouses and radiant panels in the workshop. This approach ensures optimal heat distribution and comfort in all parts of the building.

Heat consumption at the Enison hall

Heat consumption at the Enison hall

Installation and benefits of SCADA systems

The SCADA system installation was carried out with an emphasis on a wide range of control parameters. The system enables precise control of temperature, humidity and flow, and management of complex energy processes. In addition, statistical data processing allows for improved system efficiency.

Goals and expected results

SCADA system provides access to precise information and values from different systems, which leads to better management of energy consumption. Faster decision-making and coordinated operation of the system with a wide range of parameters will result in reduced consumption, shorter service intervals and extended equipment life.

Enison continues to work diligently to improve its operations and technology solutions. The integration of SCADA systems into our new office space symbolizes our commitment to innovation and the pursuit of excellence in all aspects of our business.

We invite you to follow our future news and discover how we can help you in strengthening your technological and business processes.