A revolution is taking place in mechanical engineering caused by 3D printing. Classic production, limited in terms of design and flexibility, is slowly losing its advantage in front of the wide range of design and functionality (components) optimization opportunities provided by 3D printing. After reading this text, visit https://enison.hr/3d-print/ and we will find a solution for you.

One of the main advantages is the ability to create ergonomic shapes tailored to specific customer needs. This technology also allows the creation of complex geometries and unique shapes that would be almost impossible to achieve with traditional manufacturing methods. Another significant advantage is the ability to create a lattice structure, which provides the same strength of components with significantly less weight. This is especially useful in applications where weight is a key factor.

Further advantages include the possibility of implementing individual requirements in terms of color and branding, which contributes to the personalization and recognition of the product. The possibility of obtaining specific surface textures tailored to specific applications is another advantage of this technology. Finally, 3D printing allows the integration of different components within a single product, which simplifies the production process and reduces overall production costs.

We would particularly highlight the advantages:

- Improved product quality – 3D printing enables the production of components that are of high precision and quality. Digital production enables precise implementation of complex shapes and ensures consistent product quality.

- Shorter development time – By eliminating complex tools and molds, ideas and the process of creating prototype variants can be significantly accelerated.

- Expansion of the product range / catalog – The use of 3D printing enables the production of customized components, which provides new production possibilities and the opening of new markets.

Specific applications in mechanical engineering:

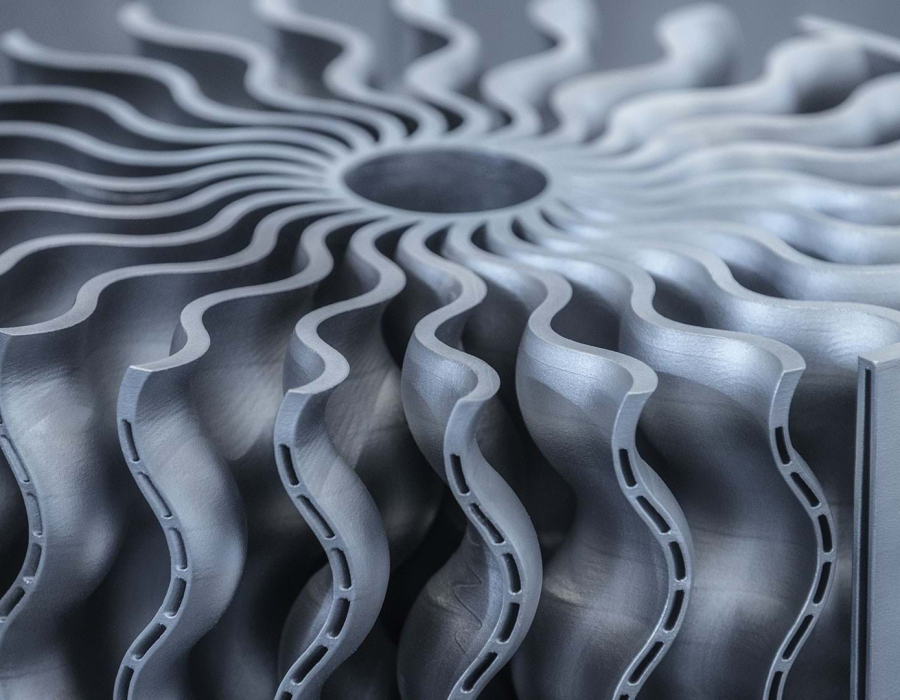

- Heat exchangers – by implementing complex geometries to optimize heat transfer and reduce mass, resulting in higher exchanger efficiency, this application is one of the most sought-after in mechanical engineering.

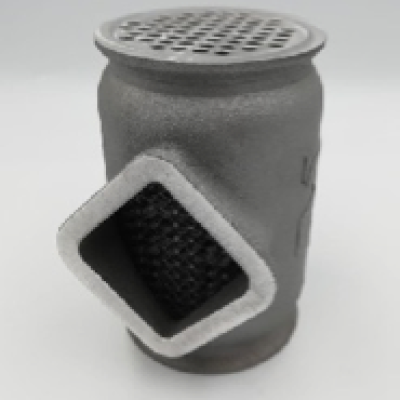

- Cable distributor – by customizing the design of components, where there are practically no limits, space and resource savings can be achieved with an optimal solution.

- Pipe distributors

- Mounting/installation brackets

- Covers

- Housings in robotics

- Positioners in automation systems – for fast, customized solutions in prototyping or series production

Visit https://enison.hr/3d-print/